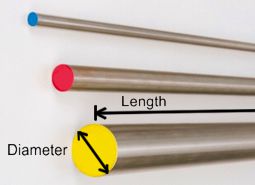

What is Drill Rod?

Drill Rod (DR) is tool steel manufactured into round bars and precision ground to insure that the diameter is bright, clean, and free of surface defects and carburization. It may also be referred to as precision drill rod, bar stock, round stock, or drill stock. After the grinding process, a polishing process is normally done to insure a smooth surface finish and tightly controlled dimensional tolerances. Drill Rod can be the raw material used to manufacture drill bits, dowel pins, taps, punches, reamers, and shafts.

Drill rod is generally purchased in an annealed condition so that the tool steel can be readily machined. After machining the pieces can be heated for greater hardness and better durability.

When tool steel rods are purchased in a hardened, heat-treated condition, they may be referred to as drill blanks. Drill blanks and drill rods used for mining or for oil and gas pipelines are a different class of products which are not included in these pages.

Nominal Sizes

Drill Rod is manufactured in various sizes of diameters and lengths. In North America the greatest variety of sizes are in fractional inches. Diameters range from 1/16″ to 3″ with many fractional-inch sizes in between. Many letter-size and number-size diameters are also available. The lengths are 3 feet or 12 feet (36″ or 144″). Some manufacturers will cut 12 foot rods in half before shipment for an extra charge. This produces two 6 foot rods that may be less expensive to ship. In metric DR, the diameters range from 2mm to 30mm and the length is about one meter.

Price vs. Performance

If you need to buy DR on a tight budget, consider using W-1 steel due to its low cost. If you need a better steel type, consider O-1, which has the best cost/performance trade-off.

Both W-1 and O-1 have about the same variety of available sizes. For even better hardness and toughness consider the other tool steels such as A-2, D-2, and M-2 in that order.

If your application requires extreme shock resistance, consider S-7. If your application requires high operating temperature, consider H-13.

Delivery Time and Inventory Quantity

The lead-time before shipment is an important aspect of DR. Many manufacturers carry large inventories of finished products. The rods are prepackaged and ready to ship on the same day or next business day ordered. It may be important to you to know whether any given size is actually in stock. Only a few websites have reliable information. DieSupplies.com indicates the lead time for each DR size and whether it is on back-order.

Steel Grades, Sizes, and Manufacturers

There are about four manufacturers of DR in North American; Precision Marshall, DB&S Steel, Starrett, and Precision Brand. There are many common sizes that they all have. And there are a few remarkable, and sometimes confusing, differences. An easy way to visualize the difference is to read our Manufacturers Table which shows the steel grade, tolerance, and size of rods offered by the leading North American manufacturers.

Standard Lengths

Most drill rods are produced in 36″ (915mm) lengths. Some manufacturers also produce rods of 144″ (12 feet) in length. The longer rods are preferred by customers using bar feeders for CNC lathes to produce multiple parts from each rod. Some rod manufacturers cut the 144″ rods in half for an extra charge. This produces two 72″ rods that may be easier to handle and less costly to ship. To understand the rod lengths produced by each manufacturer please please click the link and read our Standard Lengths Table.

Manufacturer Tolerances

Drill rod manufacturers typically make their products to a uniform set of dimensional tolerances. The diameter tolerance is a plus/minus variant that changes by rod size. The length tolerance is oversize for inch rods and plus/minus for metric rods. To understand the tolerances please click the link and read our Manufacturer Tolerances Tables which show the specifications.

Steel Grades and Processing

In North America, a variety of rod sizes are offered in popular tool steel grades O-1, W-1, A-2, D-2, S-7, M-2, and H-13. The production of tool steel rods typically includes the following processes; annealing, cold drawing, precision grinding, polishing, and deburring. The rods are usually coated with rust-preventing oil before being stored or shipped. When you receive purchased rods, they should be ready for cutting and machining with conventional machine tools. You may optionally heat treated and precision grind the rods as well.

Hardness and Machinability

The hardness and machinability of drill rods depends on the diameter and the grade of steel. To understand the effects of diameter and steel, please click the link and read our Hardness and Machinability Tables.

Color Codes

Each drill rod manufacturer has its own color codes for identifying steel grades. To understand the differences between manufacturers please click the link and read our Color Code Table.

Handling and Shipping

DR should be handled and packaged with care to avoid damaging the carefully ground and polished finish. A coating of light weight oil is recommended before shipment or storage to prevent corrosion. Manufacturers typically do an excellent job of packaging DR for handling and shipment.

Storage

Rods should be kept clean and dry during storage. If stored on shelves, be sure not to exceed the shelf’s weight capacity. Temperature control is not required. The rods will need a coating of oil to prevent corrosion, especially if the storage environment has high humidity. Most manufacturers ship the rods coated with light-weight oil and the steel grade is clearly marked.

Weight

When Length and Diameter in inches are known, the weight of a rod can be estimated by the equation; Weight in pounds = Length x Diameter x Diameter x 0.222.

When Length and Diameter are given in millimeters, the weight of a rod can be estimated by the equation; Weight in Kg = (Length x Diameter x Diameter) / 162,539.

Metric vs Inch

Inch and metric drill rods are similar products with some subtle and not so subtle differences. Inch rods have a greater selection of steel grades and diameters. There are nominal fractional-inch diameters, letter-size diameters, and number-size diameters. Metric rods are produced in hard-metric diameters. We sell inch and metric DR online. Please click the links to visit our online store.

Applications

There are countless numbers of things that can be made with drill rod. For more information about using DR please click the link and visit our Applications page.